FutureMetrics discusses potential of advanced ‘black’ pellets

Energy Disrupter

ADVERTISEMENT

FutureMetrics LLC on July 5 published a new white paper that discusses the market challenges associated with “black” wood pellets and illustrates how new innovations are enabling these version 2.0 fuel pellets to gain market share.

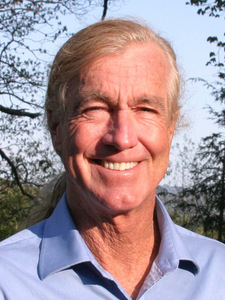

The white paper, authored by FutureMetrics President William Strauss and FutureMetrics Senior Technologist Laurenz Schmidt, opens with a description of version 1.0 white wood pellets and version 2.0 black wood pellets.

The characteristics of traditional white pellets has remained mostly unchanged for decades, the two wrote. Although white pellet manufacturing has experienced incremental improvements that yield better process reliability and consistency, improved plant safety, and lower per-ton conversion costs, Struss and Schmidt stress that the final product is essentially the same as it was 40 years ago.

“This is surprising because white pellets have several inherent challenges that have to be managed for them to be used as a low-carbon fuel in large utility power stations,” they wrote. Those challenges include an inability to withstand exposure to water and the potential for explosive dust. “The 23 million metric tonnes of industrial white wood pellets that will be transported in 2021 need to be kept dry and require robust dust management (aspiration and filtration) systems when handled,” Strauss and Schmidt wrote, noting mitigation measures to overcome those challenges require significant capital costs.

According to the paper, the costs of dry storage infrastructure contribute roughly half of the total cost of plant modifications needed to switch from coal to fuel pellets at a power station.

Alternatively, black pellets do not lose their integrity when exposed to water, have a higher bulk and energy density, result in lower logistics costs per gigajoule (GJ) delivered, and are more compatible with existing fuel pulverizers. “Higher bulk and energy density and better grindability result in the need for fewer modifications to the fuel feeding and burner systems of the coal-fueled power station in order for pellet fuel to substitute for coal,” Strauss and Schmidt wrote.

There are currently two primary technological pathways to advanced black pellets, torrefaction and steam explosion. The most universally common reason these advanced pellets have failed to gain market share is higher production costs, which has resulted in an inability to complete on the price of delivered energy with white pellets, according to Strauss and Schmidt.

“The primary cost challenge with black pellets is that there is a significant loss of solid mass during the thermal reactions resulting in an energy loss from the initial calorific value of the dry feedstock,” they wrote. There is, however, a solution to the solid mass loss and energy loss cost disadvantage. “The solution is to gain value from the mass loss,” they continued. “The compounds produced in both the SE and torrefaction reactions have a market value that is much greater than the calorific value when they are used as fuel for dryer heat.”

The paper concludes that robust future growth in the pellet sector will, in part, depend on lowering the cost of both the power station modifications and fuel itself. “Advanced thermally treated pellets can offer characteristics that significantly lower the capital cost and the time needed to modify an existing pulverized coal power station,” Strauss and Schmidt wrote.

A full copy of the white paper can be downloaded from the FutureMetrics website.