Aker supports wind blade recycling development

Energy Disrupter

Aker Offshore Wind and Aker Horizons have signed an agreement to work with a UK university to advance development of recycling solutions for old wind turbine blades.

The University of Strathclyde’s mechanical and aerospace engineering department has developed a recycling process to turn composite waste into reusable fibres.

This could help to recycle the hard-to-break-down glass-reinforced polymer composites (GRP) used in wind turbine blades, and in other sectors, including car and vessel manufacturing and oil and gas production, the partners suggested.

They will work together to scale-up and commercialise the unique process developed at Strathclyde in Scotland for thermal recovery and post-treatment of glass fibres from GRP scrap to achieve a near untouched quality.

Aker’s offshore wind (Offshore Wind) and investment (Horizons) units will contribute funding and relevant competencies – including broad expertise in chemical processing and carbon capture within the Aker group – to bring the solution to an industrial setting.

Today, nearly all thermoset GRP scrap generated in the UK and Europe – including from old wind turbine blades – goes to landfill or energy from waste.

The volume of GRP scrap is set to increase substantially. Research by the University of Strathclyde suggests a global increase of wind turbine blade waste from around 400,000 tons annually in 2030 to around two million tons by 2050.

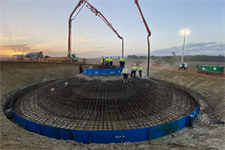

Currently, 85-90% of the content of dismantled turbines can be recycled, including the towers, foundations, generators and gearboxes. Most of these components comprise concrete, steel and cast iron which are easy to recycle, but blades are more problematic, according to WindEurope, which recently issued guidance for turbines’ end of life.