Warning over heavy lift vessel ‘bottleneck’ for offshore wind

Energy Disrupter

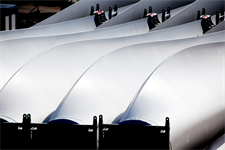

Soaring demand for specialised installation vessels has come in the wake of rapid global development and as turbine and project sizes grow, according to Rystad Energy.

The Norwegian consultancy says that by 2025, the global fleet will not be able to meet demand, meaning more orders for specialised vessel orders and conversions from oil and gas heavy lift vessels.

Rystad estimates that demand for foundation and turbine installations in 2020, in terms of the volume of offshore wind projects, will translate to about 8 and 13 years for “installation scopes” respectively.

Alexander Fløtre, Rystad Energy’s product manager for offshore wind, said: “We identify the heavy-lift vessel segment as the key bottleneck for offshore wind development from the middle of this decade, and the need for next-generation vessels may slow the cost reductions expected in offshore wind.

“Looking ahead, vessels will have to serve the initial construction phase of projects, in addition to maintaining and periodically replacing the active base of equipment. The segment that will succeed in serving the future needs of the offshore wind industry will be able to offer this valuable synergy to support a healthy fleet utilisation.”

Rystad said there are currently 32 active turbine installation vessels available, with five more that have been ordered. There are also 14 dedicated foundation installation vessels, with another five that have been ordered.

The numbers have led to a relatively oversupplied market, especially in Europe in the past few years, the consultancy said, with scale “clearly expected to tip towards an undersupply of installation vessels” by the mid-2020s.

According to Rystad Energy’s analysis – and the expectation of more offshore wind projects – demand for installation vessels could increase four- or five-fold by 2030.

At present, there are only four vessels capable of handling the next generation of turbines, such as GE’s 12-13MW Haliade-X turbine, which is expected to be operating commercially in 2021.

Current vessels have “astonishing” lifting capacities, the report said, with designs inherited from the original purpose of installing and decommissioning oil and gas platforms.

But most offshore wind projects need vessels to allow for quick and accurate positioning – often more than 300 times during installation.

Foundation and turbine manufacturing represent the most expensive parts of the development process, but this is followed by the installation phase, which accounts for up to 30% of total capital expenditures.

Typically, for 100 turbines in a 1GW project, that could mean US$800 million to $1 billion capital expenditure on the installation phase.

About 15-20% goes to foundation costs while 8-10% is for turbine installation costs.

Rystad said that across the global fleet of installation vessels it tracks, the average installation takes three to four days per vessel for each monopile.

Turbine installation times vary more widely – generally between two and five days – due to the impact of weather when lifting blades and hub components, especially at height and in windy conditions.

Solutions to increased demand

Back in January, the GustoMSC Telescopic Leg Crane won the Windpower Monthly turbine of the year innovations gold medal, as an example of one possible solution to increased demand.

The revolutionary design was developed for installation vessels capable of handling 20MW-plus offshore turbines.

The Dutch maritime engineering consultancy built a 1:20 scale telescopic leg crane, with a full-scale system due to be completed in 2022.

It sits on a self-propelled vessel operating at depths of up to 65 metres.

[embedded content]

Earlier this year, Siemens Gamesa, Ørsted and vessels supplier Esvagt announced an exploration of how drones could be used to transport tools and spare parts to offshore wind farm technicians working on turbines.

The drones were being used to deliver 3-4kg packages, with challenges identified as avoiding nacelles and blades, the impact of winds, and the effect of steel structures on a drone’s navigation systems.