Breaking ground: drill bits and the Utah FORGE geothermal project

Energy Disrupter

Drilling deep at the the Utah FORGE project requires strong

Geothermal energy is gaining attention throughout the world as an attractive energy source due to its energy production reliability. Heat in the ground is always available for energy conversion and is never weather dependent, while the reliability of other renewable energy sources is much more volatile and subject to mother nature.

However, the economic viability of geothermal energy production is adversely affected by the high cost of drilling, completion, and production. Well construction is a leading contributor to the economic imbalance of geothermal energy, as the wells are subject to harsh drilling environments, including extremely high downhole temperatures, high-strength igneous or metamorphic rock formations, and complex well geometries. These formations, often quartz-rich, can be hard and abrasive. Jordan Self and Matt Stevenson of NOV ReedHycalog describe how their company addresses these challenges in this guest post for ThinkGeoEnergy.

Traditionally, roller cone (RC) drill bits with tungsten carbide inserts are used to drill igneous rock formations, and weight is applied to fail the rock. Minor scraping is accomplished with very slight cone angles, causing the cones to roll off-center. RC seals and bearings are critical to run life, as their moving parts are exposed to friction with high weight and rotation. Multiple bits and time-consuming tripping operations are required to reach the total depth of geothermal wells, adversely affecting economic viability.

Conversely, the rock typically encountered in conventional oil and gas drilling is relatively lower in strength and less abrasive. This environment allowed for the development of fixed cutter drill bits utilizing polycrystalline diamond compact (PDC) cutters to fail the rock. With fixed cutter bits, weight is applied to gain sufficient depth into the rock, and the cutting structure is rotated and drawn through the rock to shear the formation. Shearing, as opposed to the crushing action of RC bits, is much more efficient.

PDC drill bits have almost completely displaced RC bits in conventional oil and gas operations across the globe. PDC drill bits drill longer intervals with higher rates of penetration in softer carbonate and sedimentary rock formations. In extreme drilling environments, including geothermal with igneous rock formations, RC bits have a long history of dominating a market where legacy fixed cutter PDC bits could not survive or compete. RC bits have been the preferred, economical approach in hard-rock applications until 2020, when the Utah Frontier Observatory for Research in Geothermal Energy (FORGE) project used the latest PDC technology to drill an entire geothermal well.

Utah FORGE is a major research project based at the University of Utah and funded by the United States Department of Energy (DOE). Its mission is to develop methods and tools to balance the economics of geothermal energy by driving down cost. The drilling of FORGE 16(A) 78-32 well began in 2020, as ThinkGeoEnergy reported, and the ambitious drilling team was determined to prove the effectiveness of PDC bits. The well had all the typical obstacles found in geothermal drilling (hard granitoid formations approaching confined compressive strengths of 60,000-psi and a complex well geometry with vertical, curve, and long tangent sections). A previous vertical offset well, the FORGE 58-32, drilled in 2017, took 17 drilling bottom-hole assemblies (BHA) and 51 days to drill. Total depth of that well was 7,525-ft measured depth (MD). The granite top in well 58-32 was at 3,200-ft MD, leaving 4,325 ft of hard igneous rock to drill. In the granite portion alone, 13 8¾-in. bits were required. Utilizing mostly RC bits, they averaged 325-ft per run at an average rate of 9.8 ft/hr. PDC bit trials were conducted on the 58-32 well, but RC bits outperformed and remained the preferred bit type throughout the well.

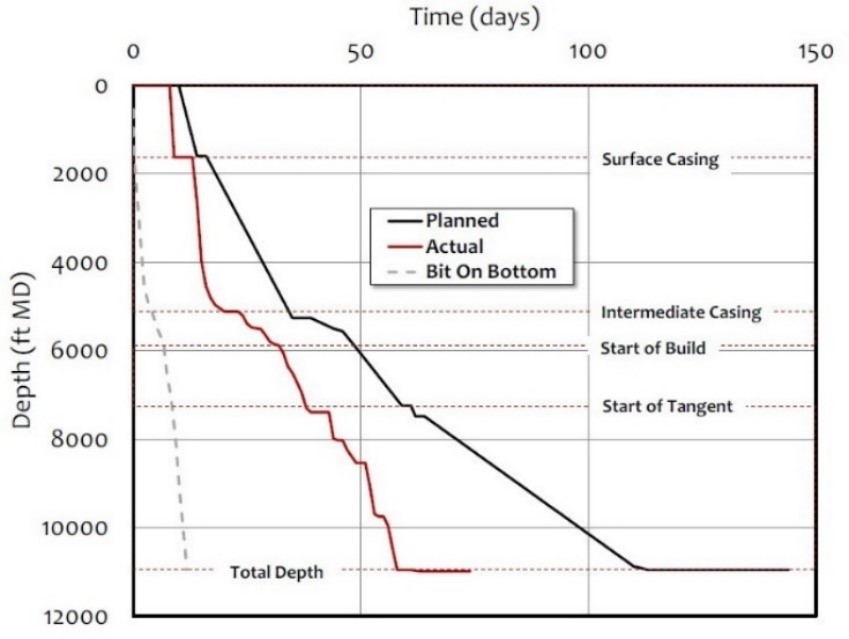

Given the overall performance on the 58-32 well and the complexity of the 16(A) 78-32 well (build angle to 65° and hold tangent, in granite, to 10,955-ft MD), 112 days were planned for drilling the well.

Following the 12¼-in. section, and well into hard granite formations, Utah FORGE personnel began aggressive PDC bit trials in the 8¾-in. vertical section. Three 8¾-in. PDC bits completed the vertical section, and the average footage per bit was 234 ft drilled at 21 ft/hr. Compared with offset performance, average footage drilled was less, yet rate of penetration (ROP) was higher. Given the higher ROP, combined with the dull condition of the PDC cutters, there was increased confidence that PDC bit and cutter technology had finally reached the point of competing with RC bits in geothermal applications.

Through the 8¾-in. curve and lateral sections, the Utah FORGE staff worked closely with the ReedHycalog team to analyze performance, review cutter-failure mechanisms, and optimize parameters. Various elements of the operation were changed and adjusted with each bit run. After careful analysis, the drill bit designs, cutter layouts, and PDC cutter selections were modified and implemented during well operations. The PDC cutter shape was effectively modified throughout the well. The last three bits in the well averaged 630-ft (194% improvement over the first three 8¾-in. bit runs) and averaged 50 ft/hr (138% improvement over the first three 8¾-in. bit runs), achieving continuous improvement for these runs.

Throughout well 16(A) 78-32, the collaboration between Utah FORGE, ReedHycalog, and advisors from Texas A&M University led to dramatic improvements in footage drilled and rates of penetration with each drill bit run. Utah FORGE completed the drilling of the 16(A) 78-32 in 52 days, spud to total depth (TD), which was an impressive 60 days ahead of schedule. Additionally, the DOE awarded USD 46 million of funding for 17 more FORGE projects with the goal of making geothermal energy a viable and economical supplement to renewable and nonrenewable energy sources.

“Beyond attention to bit and BHA mechanics, geothermal application of mechanical-specific energy concepts, and a workflow to integrate it with shock and vibration indicators improved performance. Careful tuning of the mud motors’ power sections eliminated motor failure and enhanced PDC performance,” said President of Red Resources, Inc., Duane Winkler. “Real-time and daily interactions between the ReedHycalog engineering team, consultants from Texas A&M University, and the FORGE field staff afforded in-depth evaluation and nuanced on-the-fly modifications.”

For additional information, contact Jordan Self, NOV ReedHycalog sales engineer at Jordan.Self@nov.com or Matt Stevenson, NOV ReedHycalog account manager at Matt.Stevenson@nov.com.