Wood pellets offer pragmatic solution to need for on-demand power

Energy Disrupter

ADVERTISEMENT

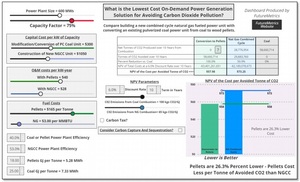

A new white paper released by FutureMetrics explains why repurposing existing pulverized coal power plants to run on industrial wood pellets is a rational and pragmatic solution to generate on-demand electricity as we transition to a decarbonized power sector.

The paper, authored by FutureMetrics President and Founder William Strauss, explains on-demand generation will be needed for a decade or more as the power sector is decarbonized. Natural gas-fueled combined cycle generating units are often cited by policymakers and utilities as a compromise between coal and the need for on-demand low-carbon power, he said.

Strauss explains natural gas is often perceived as a favorable solution due to the relatively low cost to build a new efficient combined cycle power plant when compared to nuclear and hydro. It is also relatively quick to build natural gas-fueled facilities, while the cost of natural gas itself is at historic lows.

If the goal, however, is to lower carbon dioxide (CO2) emissions in the power sector, Strauss stresses that modifying existing coal-fired power plants to run on industrial wood pellets provides a significantly higher CO2 reduction at a lower net monetary cost per avoided metric ton. His analysis shows that converting a modern pulverized coal power station to use sustainably sourced pellet fuel instead of coal results in a 26.3 percent lower cost per avoided metric ton of CO2. For power stations with lower capacity factors, the results are even for favorable for the pellet conversion scenario, Strauss said in the paper.

“The current trend of retiring coal fired power plants and building new high efficiency natural gas fired plants is rational if minimizing operating costs is the only decision metric and there is no benefit to minimizing carbon emissions,” Strauss wrote. “However, if policymakers’ primary goal is to lower carbon emissions, it makes better economic and environment sense to choose the pathway with the lowest total cost per avoided [metric ton] of CO2.”

Strauss also stresses that converting coal plants to pellets cannot replace all of the on-demand generation fleet. “The quantity of industrial wood pellets that could be produced is limited by the sustainability requirements that govern the sourcing of the pellet fuel feedstock,” he wrote. “The limits are defined by how much feedstock can be sourced without depleting the carbon stock held by the continuously growing/renewing biomass resource. But as long as the extraction rates do not exceed the growth rates, the carbon benefits can be realized because there is no net new carbon added to the atmosphere from the combustion of the fuel produced from sustainable sources.

“Carbohydrate based fuels that are derived from continuously renewing biomass sources are carbon neutral in combustion,” Strauss added. “Hydrocarbon based fuels, which are mined and extracted from the earth, always increase the concentration of CO2 in the atmosphere.”

A full copy of the white paper and a related dashboard can be found on the FutureMetrics website.