Plastic Recycling Innovation ⚙️

Energy Disrupter

Plastic Recycling Innovation ⚙️: Australia has had a problem with waste for quite some time now. Every day, we find tonnes and tonnes of waste finding their way into landfills – approximately about the size of 3 or 4 basketball courts. 2018 certainly did not help us with China now refusing the world’s (Australia certainly included) waste. But in that same year, something innovative was launched.

In 2018, Australia launched the world’s first micro-recycling factory. What is it? What does it do? Is it something that can eradicate waste completely? We will discuss everything with you in this blog. Read on to learn more.

>Download Now: Free PDF Business Owners Guide To Commingled Recycling Bin Services

A Bit About Waster

Before we discuss plastic recycling innovation, let me share with you more information about Waster.

We here at Waster provide you with innovative solutions for you and your business’s waste management and recycling needs. Furthermore, we provide flexible, 30-day contracts instead of the typical lock-in contracts, which proves to be better.

Click on the blue button to learn more.

READ: Beer Can And Bottle Recycling 🍺

Discussing This Plastic Recycling Innovation

We finally have the solution we need to counter our lingering waste problem here. We can now find it and rely on micro-recycling factories to deal with plastics which includes e-waste, as well. In particular, these micro-recycling factories were developed by the team at UNSW’s Centre for Sustainable Materials Research and Technology (SMaRT Centre, for short). Furthermore, for everyone’s information, Professor Veena Sahajwalla spearheaded the creation of the plastic recycling innovation Australia experiences today.

In general, what these types of technology do is they take in different waste streams and transform it into useful materials. These waste streams include e-waste, plastic, timber, and glass at the moment.

How Can These Micro-Recycling Further Help Us?

Aside from it obviously reducing waste from going into landfills and turning it into something more useful, we can find other benefits from it. First, this plastic recycling innovation movement can provide new jobs for people. Additionally, it moves away from the usual often too large and inflexible factories. These micro-recycling factories are extremely small and can be easily located wherever they need to be – places with lots of accumulated waste.

Lastly, with this, we will never need to rely (or at least lessen relying) on importing filaments from other countries. That is because the micro-recycling factory can also produce high-quality filaments used for 3D printing.

[embedded content]

Innovative Ways To Recycle… One Module At A Time

Also, unlike the usual factories, these micro-recycling factories consist of one or more machine that can transform waste products into something useful or new.

For example, we will go and discuss the e-waste micro-recycling factory we are talking about earlier. In particular, it reforms discarded computers, mobile phones and printers and has small modules which can fit into a small space. As for the process, the discarded devices are first placed into a module to break them down.

After that comes the next module. The next module may involve a special robot to identify and extract useful parts. This plastic recycling innovation process then involves another module. This module specifically involves using a small furnace which transforms the said useful parts into valuable materials by using controlled temperature through pure and honest research.

The materials include metal alloys and a range of micro materials used in industrial-grade ceramics. As for the specific quality plastics from computers, printers and other discarded sources, they can be put through another module that produces filaments suitable for 3D-printing applications. Finally, metal alloys are used as metal components for new or existing manufacturing processes.

Is There Any Problem With This Recycling Innovation?

You may wonder, with all of the positives this plastic, glass, timber, and e-waste recycling innovation has, does it also have negatives? The answer is yes, it does have one problem.

The main problem, like any other problem, is its high cost. The completed version of a micro-recycling factory ranges up to 1 million dollars. But as stated above, if in case a local council cannot afford the completed factory, it can opt to utilise one very much-needed module.

They can then upgrade the micro-recycling factory if needed at a later time.

Additional Statements

For this to work, we also need to be more responsible for our produced waste. Lessen waste as much as possible. Throw your rubbish into the appropriate bin. If it is recyclable, throw it in the recycling bin. Never throw recyclables in the general waste bin so it would not go into landfills.

Plastic Recycling Innovation: Quick Conclusion

Expect more of these plastic recycling innovation a.k.a. micro-recycling factories in the future for more sustainable and affordable resource recovery and recycling. It is still a relatively new project, after all. But even with its freshness, it still shows so much promise. We here at Waster can’t wait to see it!

Found this blog interesting? Check out our other blogs! Read our blogs on gig economy jobs in Australia and recycling sales job if you are interested in looking for some ways to earn.

If You Are A Small Or Medium Business…

Are you a small or medium business based in Australia? Are you in need of various waste management and recycling services? How about the shredding and disposal of your private and sensitive documents? Maybe you also need someone to clean your grease trap; Waster offers all of these services!

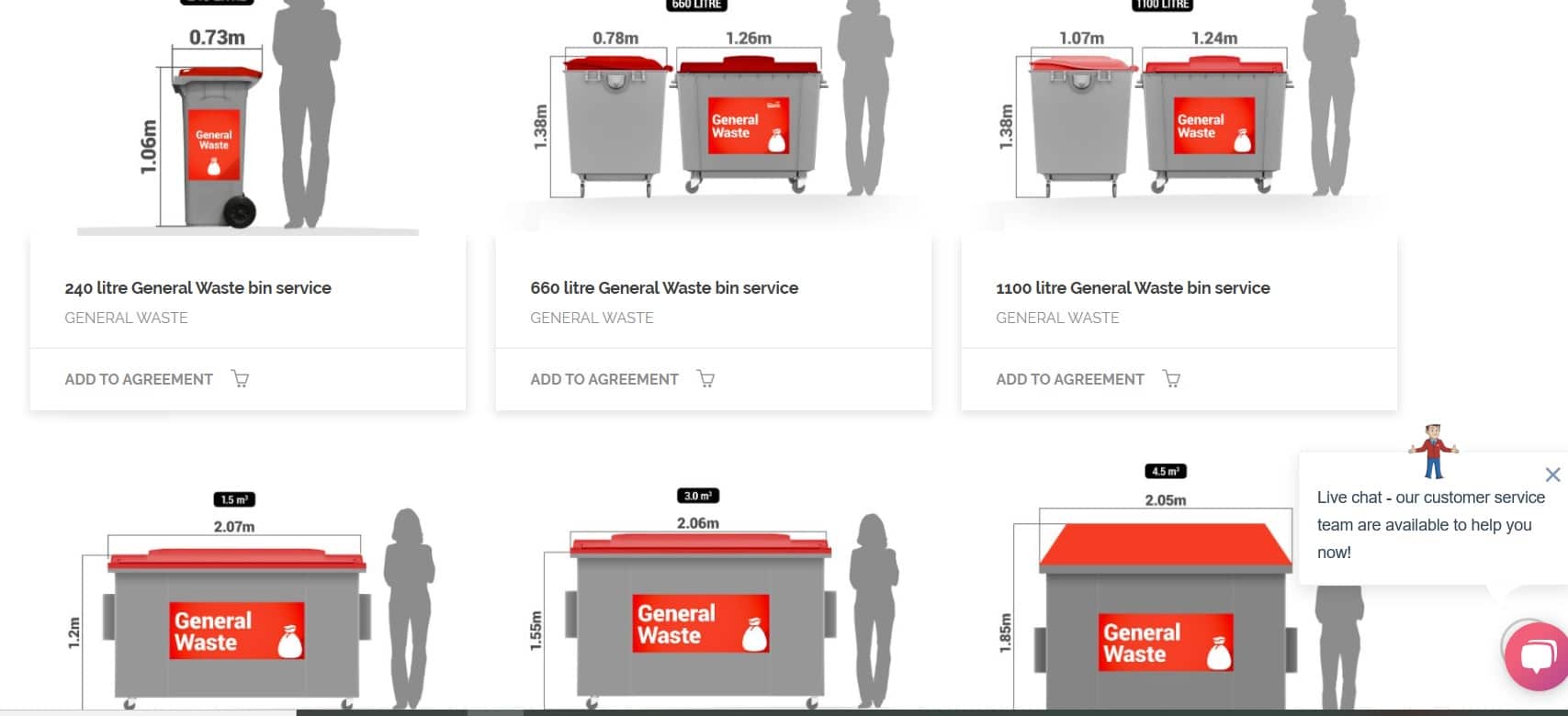

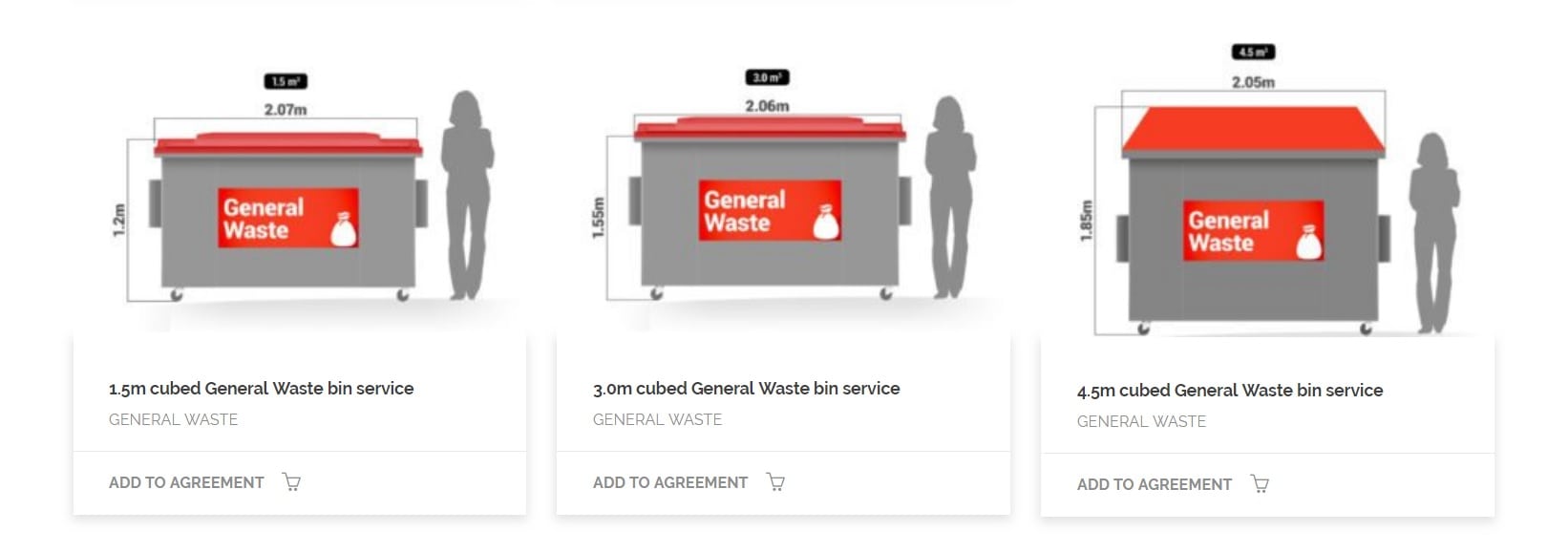

Examples of our service include general waste, cheap cardboard recycling, commingled recycling, medical waste disposal, secure document shredding, sanitary bins and any other services – many of which could help with the plastic recycling innovation efforts.

You only need to click the blue button for more information.

Waster: Things You Need To Know

If you’re looking for different bin services, check our waste recycling shop and find the best deals in terms of pricing and services.

Also, please call 1300 WASTER (1300 927 837), or email us at [email protected] if you have any further questions.