Webinar recap – Utah FORGE Status and Lookahead

Energy Disrupter

In a recent webinar by ThinkGeoEnergy and Enerchange, Dr. John McLennan of Utah FORGE provided updates and details on the next steps of this pioneering EGS project.

ThinkGeoEnergy and Enerchange recently hosted a webinar with Dr. John McLennan, Prof. Chemical Engineering at the University of Utah, and Utah FORGE – Co-Principal Investigator as part of the regular IGC Webinar Series.

During the webinar titled Utah FORGE (Frontier Observatory for Research in Geothermal Energy): Status and Lookahead, Dr. McLennan shared updates on the groundbreaking EGS research project. provided some details on the project’s next steps, and gave some insight on how the findings at Utah FORGE can revitalize other EGS projects.

Below is a recap of the topics that were discussed during the webinar. The recording of the webinar can also be viewed here:

[embedded content]

Project concept and drilling strategy

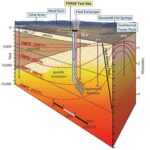

The Utah FORGE project aims to test EGS technologies to enhance or promote the commercialization of EGS sites. The project is funded by the U.S. Department of Energy and managed by the Energy & Geoscience Institute at the University of Utah. The project site is located southwest Utah near the town of Milford.

Six wells have been drilled at the Utah FORGE site so far. Drilling of the reinjection well 16A was completed in Winter 2021, as we reported. This is a deviated well drilled 65 degrees to the vertical and a total vertical depth of 8559 feet and a measured depth of 10,987 feet. The surrounding wells will be used for monitoring and have been outfitted with geophones and other sensors to detect and triangulate the locations of microseismic events.

Well 16A is a high-enthalpy well with a bottom hole temperature of 230 degrees Celsius. The plan is to stimulate fractures at the toe of this well, monitor the microseismic events during stimulation, and drill a production well into the microseismic cloud.

Stimulation and seismic monitoring

Hydraulic stimulation of well 16A was done in three stages. For each stage, slickwater with an organic tracer was pumped into the well with constant monitoring of fluid flowrate and well pressure. The well was then shut in and monitored for pressure decline, after which the fluid was flowed back.

At the conclusion of each stage, a bridge plug was ran to isolate the previous stage. After setting the bridge, a perforating gun was ran into the hole to create entry from wellbore to the formation in preparation for the subsequent stimulation stage. Dr. McLennan provided some details of each stimulation stage and insight on the results.

Stage 1 was done at the openhole portion of the well at a depth of about 10,787 feet. 4261 bbl of slickwater was pumped in this stage, reaching a maximum injection rate of 50 bpm.

After isolation of Stage 1, Stage 2 was done above the 7-inch shoe. Perforation was done from 10,560 to 10,580 feet of measured depth. 2,777 bbl of slickwater was pumped, reaching a maximum injection rate of 35 bpm.

Isolation of Stage 2 was done, after which perforation of the casing was done from 10,120 to 10,140 feet measured depth. A crosslinked fluid with microproppant was injected during Stage 3. The total pumped volume was 3,016 bbl.

After Stage 3, the two bridge plugs were retrieved. On April 23, 2022, the rig started rig-down operations.

Among the lessons learned during the stimulation stage was the success of using bridge plugs to isolate fracture zones, as well as the use of pressure profiles paired with microseismic data to infer fracture geometries.

One of the more interesting results is that there was no interaction between the different tracers used for each stimulation stage, implying that there is no interaction between the stimulated fracture systems. The use of tracers will help mitigate the risk of short-circuits, one of the more common issues in EGS projects.

Next steps

The next stage of the project is to drill a production well that will intersect the fracture network that was stimulated from well 16A. This well will help evaluate the connectivity and conductivity of the stimulated fractures. Conformance, or the equality of flow between fracture systems, will also be evaluated. Lastly, the conversion of thermal energy to power production in the project site will be assessed.

However, data analysis and numerical modeling will need to be completed before the project can move the next stage. The target is for the drilling of production well 16B to start later this year. This will be drilled with a similar trajectory as 16A and will terminate immediately vertically above the injection well with a separation in the magnitude of 300 feet. The plan is also to collect cores from the drilling to help identify intersection with fractures.

Findings from the Utah FORGE project can help revitalize and accelerate development in pre-identified EGS sites. The U.S. Department of Energy had initially allocated 5 such sites for paper studies that meet the criteria for EGS sites – temperature above 175 degrees Celsius, a crystalline granitic igneous reservoir, minimal seismic considerations, and favorable environmental conditions.

We would like to thank Dr. John McLennan for this engaging and insightful webinar on the Utah FORGE project. Much more details about the project and preliminary results were discussed during the webinar and all of these are available in the recording as linked below.

Source: Webinar recording via Enerchange YouTube channel