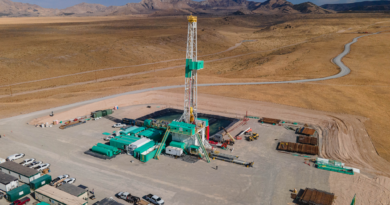

The technology trends for future geothermal energy projects

Energy Disrupter

An article from Baker Hughes discusses the five technology trends that will help in the development of untapped geothermal resources.

Dr. Ghazal Izadi, the Global Discipline Lead for Unconventionals and Geothermal Reservoir Technical Services of Baker Hughes, has written an article identifying five technology trends that will drive the geothermal industry forward. These technologies mostly focus on accessing previously untapped resources and ensuring that such projects are economically feasible. The full article can be accessed here.

“There are a lot of other opportunities where our technology can convert the geothermal heat below the earth to geothermal energy – we assess the right application based on each geothermal development project,” says Dr. Ghazal Izadi. “Geothermal energy will be an essential part of the future energy mix – it can provide baseload power when the wind is not blowing, or the sun is not shining. Developing a balanced mix of these renewables will ensure energy security.”

- Holistic approach

Modern geothermal technical services provide a holistic approach to development by offering solutions that both assess the subsurface resource and design surface systems. This provides a more complete picture of the economic feasibility of the project as well as lowers the project risks, reduces turnaround time, and improves the system’s performance.

- Solutions for enhanced geothermal systems

Enhanced geothermal systems (EGS) refer to systems that do not have sufficient innate permeability or fluids. The solution for this is to stimulate the system using fluid pressure. EGS has been a major area of research for geothermal developers and research institutes worldwide. We recently published an article on the underground research lab of the Pacific Northwest National Laboratory (PNNL) focused on EGS.

Digital technologies are expected to play a vital role in making EGS projects feasible. Modeling software allows for reservoirs to be represented as digital twins to provide critical insight to geothermal systems. Monitoring systems allow for real-time data gathering from downhole and surface sensors. There has also been progress in developing remote drilling systems that allow for drilling in projects without having to send crew to the field.

- New materials

The subsurface conditions in a geothermal system can be very challenging. Materials used for wells and downhole equipment must be able to withstand extreme temperatures and pressures, as well as the corrosive nature of geothermal fluids.

The Integrated Well Services (IWS) of Baker Hughes has developed an automatic vertical drilling system that ensures a perfectly vertical drilling path. This minimizes contact between the casing and the borehole, thus retaining well integrity. The use of non-metallic flexible pipes for geothermal fluids also reduces the effect of corrosion on surface facilities.

Other efforts in this space include the development of the TenarisHydril Wedge 563 (R) Corrosion Barrier internal coating by Tenaris. This offers a much more cost-effective alternative to Corrosion Resistant Alloys (CRA) in downhole equipment.

- Supercritical geothermal

Ultra-hot supercritical geothermal systems have the potential to generate ten times more power with less water used and CO2 generated compared to conventional hydrothermal systems. However, there are numerous challenges associated with developing such projects including increased drilling depth and more aggressive geothermal fluids.

Baker Hughes is currently working with Alta Rock Energy to develop super-hot rock geothermal project in Newberry Volcano in Oregon, USA. This is also the main focus of the Geothermal The Next Generation project.

- Additive manufacturing

Additive manufacturing, more colloquially referred to as 3D printing, refers to a manufacturing process that is based on the controlled layer-by-layer deposition of materials into precise geometric shapes. This gives way to the use of novel material to create parts in geometries that would not have been possible with more traditional manufacturing techniques.

Although the application of additive manufacturing in geothermal is still limited, the potential for this technology continues to be explored. The finalist entry of Baker Hughes in the American-Made Challenges Geothermal Manufacturing Prize is a backup ring for ultra-expansion high-pressure high-temperature (HPHT) packers for zonal isolation in geothermal wells. Additive manufacturing combined with machining was used to help these components withstand HPHT conditions.

Source: Baker Hughes