Conveyor Technology:Designing for the Future by Innovating the Present

Energy Disrupter

Bulk handling is evolving when it comes to safety, efficiency and automation.

ADVERTISEMENT

Higher production demands across all bulk handling segments require increased efficiency at the lowest cost of operation, in the safest and most effective manner possible. As conveyor systems become wider, faster and longer, more energy output and more controlled throughput will be needed. Add an increasingly stringent regulatory environment, and cost-conscious plant managers must closely review which new equipment and design options align with their long-term goals for the best return on investment.

Safety at Higher Belt Speeds

Safety is likely to become a new source of cost reduction. The percentage of processing facilities with a robust safety culture are likely to increase over the next 30 years to the point where it is the norm, not the exception. In most cases, with only a marginal adjustment to the belt speed, operators quickly discover unanticipated problems in existing equipment and workplace safety. These problems are commonly indicated by the larger volume of spillage, increased dust emissions, belt misalignment and more frequent equipment wear and failures.

Higher volumes of cargo on the belt can produce more spillage and fugitive material around the system, which can pose a tripping hazard. According to the U.S. Occupational Safety and Health Administration, slips, trips and falls account for 15% of all workplace deaths and 25% of all workplace injury claims. Moreover, higher belt speeds make pinch and sheer points in the conveyor more deadly, as reaction times are drastically reduced when a worker gets clothing, a tool or a limb caught from incidental contact.

The faster the belt, the quicker the belt wanders and the harder it is for a belt tracker to compensate, leading to spillage along the entire belt path. Caused by uncentered cargo, seized idlers or other reasons, the belt can rapidly come in contact with the mainframe, shredding the edge and potentially causing a friction fire. Beyond workplace safety consequences, the belt can convey a fire throughout the facility at extremely high speed.

Another workplace hazard—one that is becoming progressively more regulated—is dust emissions. An increase in the volume of cargo means greater weight at higher belt speeds, causing more vibration on the system and leading to reduced air quality from dust. In addition, cleaning blade efficiency declines as volumes rise, causing more fugitive emissions during the belt’s return. Abrasive particulates can foul rolling components and cause them to seize, raising the possibility of a friction fire and increasing maintenance costs and downtime. Further, lower air quality can result in fines and forced stoppages by inspectors.

Modern Chute Design

Wider and faster conveyors are being deployed to drive down the per-ton cost of conveyed material. Traditional troughed designs will likely remain a standard, but the push toward wider and higher-speed belts will require substantial development in more reliable components, such as idlers, impact beds and chutes.

A major issue with most standard chute designs is that they are not engineered to manage escalating production demands. Bulk material unloading from a transfer chute onto a fast-moving belt can shift the flow of material in the chute, resulting in off-center loading, increasing fugitive material spillage and emitting dust well after leaving the settling zone. The result of off-center loading is mistracking and spillage around the system and walkways.

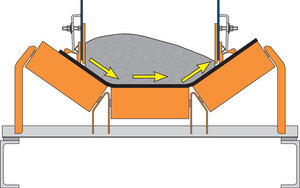

Newer transfer chute designs aid in centering material onto the belt in a well-sealed environment that maximizes throughput, limits spillage, reduces fugitive dust and minimizes common workplace injury hazards. Rather than material falling with high impact directly onto the belt, the cargo’s descent is controlled to promote belt health and extend the life of the impact bed and idlers by limiting the force of the cargo at the loading zone. Reduced turbulence is easier on the wear liner and skirting, and lowers the chance of fugitive material being caught between the skirt and belt, which can cause friction damage and belt fraying.

Longer and taller than previous designs, modular stilling zones allow cargo time to settle, providing more space and time for air to slow down, so dust settles more completely. Modular designs easily accommodate future capacity modifications. An external wear liner can be changed from outside of the chute, rather than requiring dangerous chute entry as in previous designs. Chute covers with internal dust curtains control airflow down the length of the chute, allowing dust to agglomerate on the curtains and eventually fall back onto the belt in larger clumps. And dual skirt sealing systems have a primary and secondary sealing strip in a two-sided elastomer strip that helps prevent spillage and dust from escaping from the sides of the chute.

Rethinking Belt Cleaning

Faster belt speeds can also cause higher operating temperatures and increased degradation of cleaner blades. Larger volumes of cargo approaching at a high velocity hit primary blades with greater force, causing some designs to wear quickly, leading to more carryback and increased spillage and dust. In attempt to compensate for lower equipment life, manufacturers may reduce the cost of belt cleaners, but this is an unsustainable solution that doesn’t eliminate the additional downtime associated with cleaner servicing and regular blade changes.

As some blade manufacturers struggle to keep up with changing production demands, industry leaders in conveyor solutions have reinvented the cleaner industry by offering heavy-duty, engineered polyurethane blades made to order and cut on-site to ensure the freshest and longest-lasting product. Using a twist, spring or pneumatic tensioner, the primary cleaners are forgiving to the belt and splice but are still highly effective for dislodging carryback. For the heaviest applications, one primary cleaner design features a matrix of tungsten carbide scrapers installed diagonally to form a 3-dimensional curve around the head pulley. Field service has determined that it typically delivers up to four times the service life of urethane primary cleaners, without ever needing retensioning.

Taking belt cleaner technology into the future, an automated system increases blade life and belt health by removing blade contact with the belt any time the conveyor is running empty. Additionally, it reduces labor for the constant monitoring and tensioning of blades to ensure peak performance.

Connected to a compressed air system, pneumatic tensioners are equipped with sensors that detect when the belt no longer has cargo and automatically backs the blade away, minimizing unnecessary wear to both the belt and cleaner. The result is consistently correct blade tension, reliable cleaning performance and longer blade life, all managed without operator intervention.

Bulk Handling, Safety and Automation in the Future

Automation is the way of the future, but as experienced maintenance personnel retire, younger workers entering the market will face unique challenges, with safety and maintenance skills becoming more sophisticated and essential. While still requiring basic mechanical knowledge, new maintenance personnel will also need more advanced technical understanding. This division of work requirements will make it difficult to find people with multiple skill sets, driving operators to outsource some specialized services and making maintenance contracts more common. Ultimately, conveyor monitoring tied to safety and predictive maintenance will become increasingly reliable and widespread, allowing conveyors to autonomously operate and predict maintenance needs.

Author: Todd Swinderman

CEO Emeritus, Martin Engineering

info@martin-eng.com

www.martin-eng.com