Sandia publishes compendium of geothermal drill bit performance from FORGE project

Energy Disrupter

Sandia National Laboratories has published a detailed report and compendium of PDC drill bit performance based on wells drilled at the Utah FORGE project.

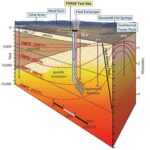

Sandia National Laboratories (SNL) has published a detailed report and compendium of drill bit performance based on the drilling of four geothermal wells as part of the Frontier Observatory for Research in Geothermal Energy (FORGE) project in southwestern Utah. The results of the study, collectively known as “Analysis of Rig Parameter Data Using Drilling Process Modeling Constraints,” are summarized in the following papers:

The analysis done by SNL on the drilling records from the FORGE project aim to provide some level of guidance on selection of the right drill bit for geothermal well drilling, based on location and depth, to reduce drilling costs.

“At the FORGE site, a number of wells were drilled to depths of approximately 10,000 feet, and they were largely drilled by polycrystalline diamond compact bits,” said David Raymond, a Sandia mechanical engineer and leader of the analysis. “This is one of the largest applications of diamond bits for geothermal drilling in their 40-year history. We produced a compendium of all the drill bits used and how they performed.”

The US DOE-funded Utah FORGE project is a dedicated underground field laboratory for developing, testing, and accelerating breakthroughs in Enhanced Geothermal Systems technologies to advance the uptake of geothermal resources around the world. Earlier this year, the FORGE team announced successful results from long-term circulation tests, indicating good connectivity across the stimulated geothermal reservoir.

The Sandia research team, led by Raymond and with mechanical engineer Melanie Schneider, analyzed drill rig data from the four wells drilled at the FORGE site, looking at the response data and post-operation photos of each polycrystalline diamond compact bit. Polycrystalline diamond compact bits have proven to be more cost effective than roller bits for oil and gas drilling. This compendium could help do the same for geothermal drilling.

Analysis for better bits

Four wells were drilled for injection, production, and monitoring at the FORGE site, primarily using polycrystalline diamond compact bits. These bits use the strength of lab-made diamonds in the form of disc-shaped cutters. Many of these cutters are embedded into the bit in a specific arrangement designed to best cut the rock. The industrial diamonds in these bits are tiny, grown in a lab for strength rather than aesthetics.

To evaluate drill bit performance, the Sandia team collected data on four key parameters — the force applied to the drill bit by the rig, the rotation speed set by operators, the drilling speed, and the power needed to achieve that speed — and inserted those numbers into a computer model. They used the algorithm to model the interaction between the drill bit and the rock, comparing that with the response of a single standardized diamond cutter.

Drilling costs were also considered by the team, analyzing the balance between drilling speed and distance drilled and how that plays into the cost per foot drilled by each bit. One of the leading costs in geothermal well drilling is the daily expense of renting a drill rig, Raymond said. However, Schneidier emphasized that this doesn’t mean drilling faster is always the most cost-effective solution. Depending on the depth already drilled and the time taken to get a fresh bit to the bottom of the well, a slower, steadier approach may be more cost effective, Raymond added.

“A big cost is truly how long it takes to get in and out of the hole when you’re at depth,” Schneider said. “A key take-away from our reporting is it’s not necessarily about going fast or with more force; it’s about trying to extend the bit’s life and getting the most out of each one. We’re already seeing a huge improvement in drilling performance throughout the course of the four wells at FORGE.”

A history of work on diamond bits

The history of diamond-based drill bits is closely intertwined with the Sandia National Laboratories. In the early 1980s, at the advent of synthetic diamond manufacturing, the US DOE sponsored research at the Sandia to develop diamond-based drill bits for drilling in geothermal systems.

Sandia researchers, led by David Glowka tested diamond cutters from various manufacturers in the lab, measuring the forces required to scratch rock depending on the cutting angle and other parameters. Data from these experiments were fed into a computer model that allowed for the simulation of forces on any drill bit design. This code was then publicly released and provided to drill bit companies to inform the design of cutters on their bits, which was instrumental in catalyzing the industry.

The oil and gas industry has since then widely adopted the use of diamond bits. However, there were challenges remaining in drilling in geothermal sites, such as the high temperature and hard rock causing the drill bits to wear out too quickly. Sandia has continues refining diamond bits for geothermal drilling over the years, doing computational modeling of specific vibrations in hard rocks, and participating in field tests to improve diamond bit usage in extremely hard rock.

Raymond hopes this compendium of bit performance at the FORGE site will help bit manufacturers in designing even better performing bits and assist geothermal well drillers in selecting the best bits for their conditions. Both should help reduce startup costs for steady, clean electricity-producing geothermal power plants.

“It’s been a long road getting to this point where polycrystalline diamond compact bits are a viable solution for geothermal drilling,” Raymond said. “It’s not intuitively obvious how you should place the cutters across the bit to balance speed and lifetime, but that is what our analysis has accomplished. There’s an incredible wealth of information here on what worked and what didn’t work on these synthetic diamond bits.”

Source: Sandia National Laboratories