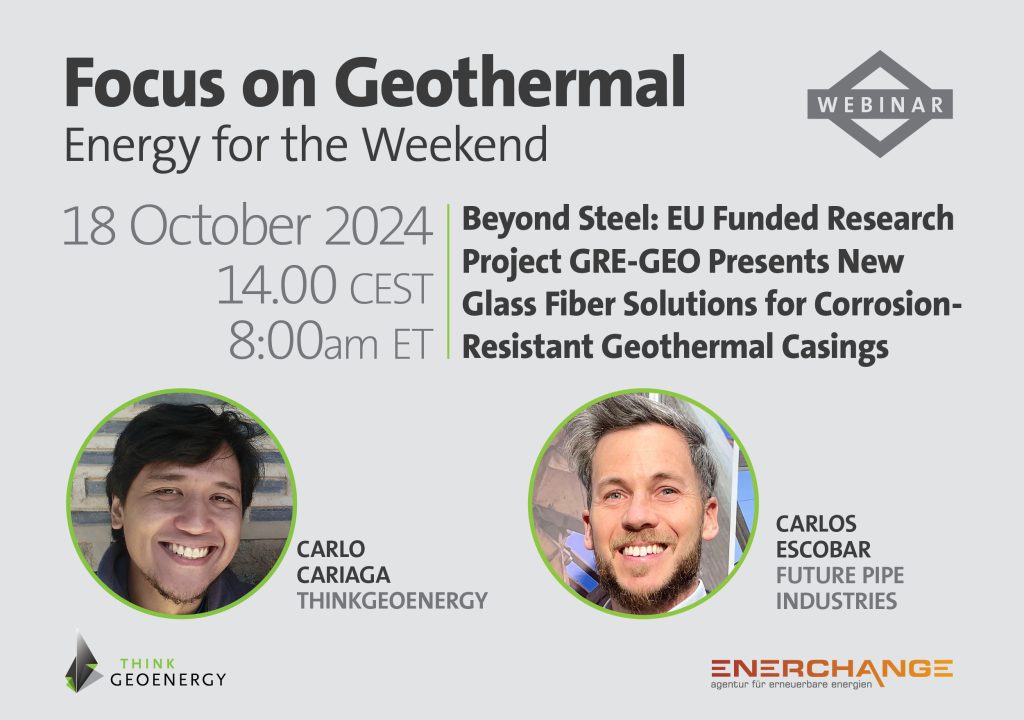

Webinar – Glass fiber reinforced epoxy for geothermal casings, 18 October 2024

Energy Disrupter

Join us for a webinar on the 18th of October on the EU-funded GRE GEO project which has developed glass fiber reinforced epoxy for geothermal applications.

As part of the regular Focus on Geothermal Webinar series – a partnership of Enerchange and ThinkGeoEnergy – we are proud to host the GRE-GEO team for a webinar on “Beyond Steel: EU Funded Research Project GRE-GEO Presents New Glass Fiber Solutions for Corrosion-Resistant Geothermal Casings.”

The multinational consortium of geothermal experts, that has launched the GEOTHERMICA project GRE-GEO has developed a new glass fiber reinforced epoxy casing system for geothermal application. Carlos Escobar (Future Pipe Industries) will lead the session. Ferid Seyidov (Vulcan Energy Resources), Leo de Mul (Dynaflow Research Group), and Javier Holzmann (TU Clausthal) will provide detailed insights into the key findings of the project.

Date: 18 October 2024

Time: 14:00 CET / 08:00 ET

Registration: Click here to register

Session Lead: Carlos Escobar

Speakers: Ferid Seyidov, Leo de Mul, Javier Holzmann

Corrosion and scaling significantly reduce the lifespan of traditionally used steel tubular systems, which must ensure the integrity of the wellbore. Consequently, workover procedures become necessary sooner than expected, resulting in a significant financial burden.

In contrast, Glassfiber Reinforced Epoxy (GRE) casing is a desirable alternative because this material is corrosion-resistant. However, compared to steel, GRE tubulars have traditionally been available only with relatively small inner diameters and excessively large outer diameters.

The GRE-GEO project (GRE casing for geothermal applications) has developed a new strategy for well completion, aiming to provide a corrosion-resistant alternative to reduce geothermal energy development and production costs while avoiding additional investment. Moreover, GRE tubulars have a significantly lower life cycle assessment (LCA), making them a more sustainable material with low embodied CO2, which is particularly important in geothermal applications. The project was carried out by a consortium of eight partners:

- Vulcan Energie Ressourcen GmbH, Germany

- DrillTec GUT GmbH, Germany

- TU Clausthal (ITE), Germany

- Future Pipe Industries (FPI), Netherlands

- Dynaflow Research Group DRG, Netherlands

- Nuclear Research and Consultancy Group NRG, Netherlands

- Eartha AG, Switzerland

- Service Industriels de Genève, Switzerland

For more information on the project, visit www.gre-geo.org or download the project flyer here.