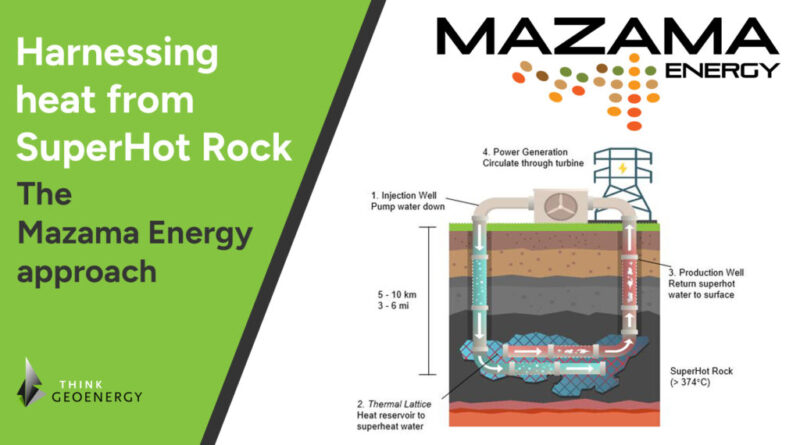

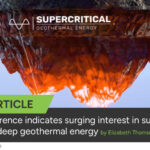

Harnessing heat from SuperHot rock: The Mazama Energy approach

Energy Disrupter

Mazama Energy is developing a suite of technologies to efficiently harness heat from SuperHot Rock resources and reinvent geothermal power generation.

In 2024, U.S. utilities had nearly doubled their forecasts of how much additional power they will need by 2028, driven primarily by demand from rapidly growing number of data centers. By 2050, it is estimated that the U.S. will require additional 700-900 GW of clean firm capacity to support increased demand. To responsibly meet this surging demand, new, scalable clean energy sources must be developed.

A promising resource is Superhot Rocks (SHR, > 374°C), which is vast and holds 100x the energy of all known fossil fuel reserves. Mazama Energy’s focus is to harvest heat from SHR to generate utility-scale, carbon-free, baseload energy.

Mazama Energy™ intends to create durable, Enhanced Geothermal Systems (EGS) in SHR to circulate water between horizontal wells and maximize heat extraction. By extracting heat with water above 374°C in the reservoir (super-critical), Mazama Energy’s wells can generate 5-7x higher power density than equivalent geothermal systems at 200°C. The high thermal density of SHR EGS will also reduce water usage by 75% compared to prevailing EGS projects.

Mazama Energy has focused on advancements in three key technology areas to develop SHR resources reliably and at a reasonable cost:

- Well engineering and construction to ensure long-life of SHR wells;

- Drilling of horizontal or near horizontal wells to increase contact with the SHR formation; and

- Creating high capacity, durable, stimulated flow paths in SHR to connect injector and producer wells.

Mazama MUSE™ (Modular Unconventional Superhot Energy)

Mazama’s MUSE™ is the synthesis of engineering and operational advancements to drive down the cost of electricity. Innovations include a patented approach to drilling and guiding horizontal wells in SHR, novel stimulation techniques to create large EGS reservoirs, and advanced heat harvesting strategies to maximize power. MUSE performance projections indicate that power projects can be developed at costs less than $50 per MWh.

SuperHot Rock (SHR) Drilling

Over the course of a three-well program, the Utah FORGE drill team reduced well drill times by more than half, with instantaneous ROP increases over 500% in the thick granite pay zone. At the same time, record footage per bit increased over 200%. Leveraging these advances to drill horizontal wells in SHR is a key consideration in Mazama Energy’s drilling technology development program.

At the 2024 Iceland Geothermal Conference, Tony Pink (Drilling Advisor) and Suri Suryanarayana (Well Technologies Chief) presented a gap analysis highlighting the technology needed to drill, case, and cement SHR geothermal wells. Their assessment was that drilling wells in SHR does not require a scientific breakthrough, but rather robust planning, extensive engineering iterations, and the determination to proceed with drilling. The current directional control tools to drill horizontal wells are not rated for SHR temperatures, so we must create the environment for them to perform.

However, Mazama Energy is currently developing a novel drilling system to enable the use of existing directional drilling tools in SHR conditions. This breakthrough uses supercritical CO2 (sCO2) as the drilling fluid and leverages Managed Pressure Drilling (MPD) techniques from oil and gas to deliver significant temperature drops across the bottom hole assembly. Combining drilling with sCO2 that can enable off-the-shelf directional drilling tools with the drilling advances made at Utah FORGE and other geothermal sites, horizontal wells in SHR will become much cheaper and more reliable.

Thermal Lattice™ – Reservoir Creation

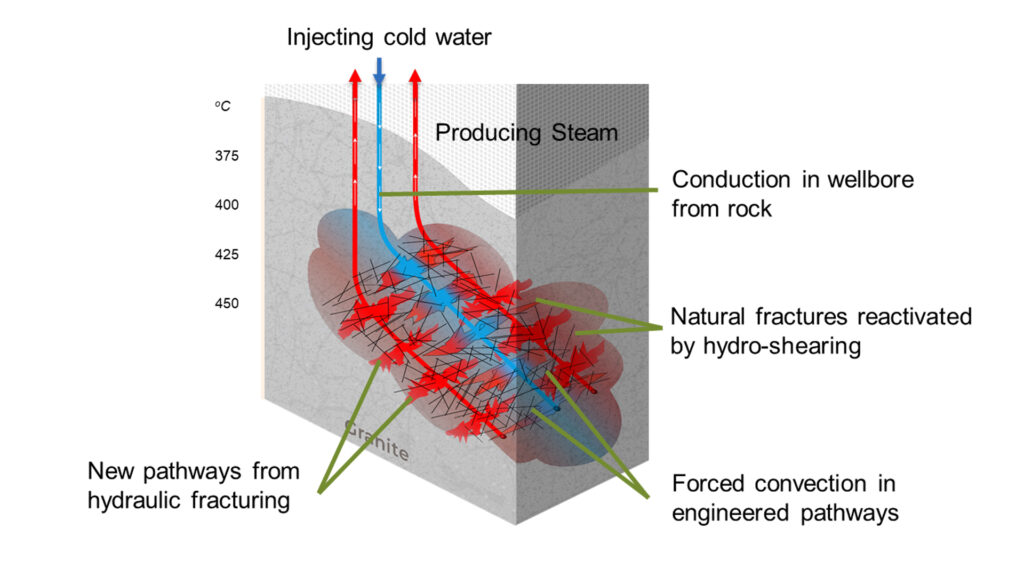

Thermal Lattice™ is Mazama Energy’s innovation for engineering high-capacity, durable geothermal reservoirs. One of the biggest challenges in harnessing heat from subsurface is achieving injector to producer fluid transfer paths that enable meaningful communication.

In most hydrothermal systems where native permeability is present, connection of injector to producer wells can be more easily established. In deep, SHR environments where host rock permeabilities are minimal, the connection between wells occur through synthetically created pathways and natural fracture systems.

Mazama Energy’s approach involves a hybrid application of various techniques to significantly enhance the stimulated rock volume. With the theoretical work completed and the experimental testing progressing well in laboratories, the creation of a sustainable EGS reservoir in SHR now appears feasible. Harnessing rock mechanics concepts, past experiences in HPHT wells and various diagnostic technology approaches will help pave the way of maximizing exposure to temperature of a future SHR well while utilizing minimal amount of fluid. In Mazama Energy’s upcoming field applications, various components of achieving effective well to well connections will be tested, including high temperature proppants and materials.

Thermal Lattice™ is not just a process, but a convergence between application and the unique needs for SHR. Mazama Energy is collaborating with various National Labs to understand the behavior of materials used in stimulation and the rock mechanics at SHR conditions. In addition, several industry partners are collaborating to accelerate technology advancements in proppants, completion tools, and fluids towards bringing Thermal Lattice™ to fruition.

Heat Harvester ™ – prediction, modelling and optimization of heat to power dynamics

To predict the performance of SHR EGS wells, Mazama has developed an Integrated Asset Management (IAM) model. Heat Harvester™ was developed to represent the entire system cycle, including injection wells, heat extraction from stimulated superhot rock, production wells, and electrical generation.

This proprietary framework is based on the fundamental physics of heat and mass transfer, encompassing conduction, convection, and advection for heat extraction from SHR. Heat Harvester uses transient pressure and enthalpy balances solved through a finite cellular model. In the cells of the model, water moves:

- down injection wells,

- through the thermal lattice designed for maximum rock contact,

- up production wells

- through steam turbines for electrical generation, and

- is finally recycled back to the injection wells.

The model can determine how to operate the entire SHR EGS project in an integrated fashion to best achieve and sustain a specified electrical power generation target. Heat Harvester™ addresses the modelling challenges of modeling water above 374°C where it becomes supercritical and its thermophysical properties change dramatically. The supercritical phase affects the pressure-temperature characteristics of a production well differently compared to conventional geothermal systems. Heat Harvester™ allows Mazama Energy to simulate and optimize Thermal Lattice™ parameters, well configurations, and development strategies to facilitate planning with consideration of economic value.

The Newberry pilot project

SHR geothermal is one of the most promising opportunities for the world to create a new, low carbon energy source. It will take innovation, ingenuity and strong collaboration between industries to make this a reality.

To advance the science needed to operate in SHR conditions and to demonstrate the immense potential of SHR, the U.S. Department of Energy (DOE) has selected Mazama Energy to demonstrate the first-of-its-kind SHR EGS pilot at Newberry, Oregon, a fully permitted site for technology testing. MUSE™ has the potential to become the lowest cost, terawatt-scale, dispatchable source of carbon-free power. Mazama Energy’s vision is to catalyze equitable energy transition by providing this clean, reliable, and affordable power for majority of the world’s population.