Interview – Building geothermal power generation capacity with ABB

Energy Disrupter

In this interview with Jonas Burström, we discuss how ABB is supporting the geothermal power generation sector and the challenges that need to be overcome.

Discussions and stories on geothermal power plants typically focus on the turbines, who is supplying them, and what technologies they use. We often overlook all the equipment that are complementary to the turbines – the generators, motors, breakers, and pumps among others.

To learn more about this aspect of power plant operations, we talked with Jonas Burström, Sales Manager for Motors and Generators at electrification and automation leader ABB. In this interview, Jonas tells us about the unique challenges of offering their products to the geothermal industry and why geothermal is a perfect fit for ABB’s overarching business philosophy.

Can you tell us about the products and services that ABB has been offering the geothermal industry?

ABB has done everything from toasters to trains to power stations. It has reshaped itself over and over. For the moment, we are a technology leader in electrification, automation, and robotic with about 105,000 employees.

ABB used to produce complete power plants, but this is a business that we discontinued about 20 years ago.

The motors and generators business, where I belong, serves all kinds of customers around the world. This includes geothermal applications. While we do not deliver complete power plants anymore, we certainly have a lot of equipment that can go into this discipline like generators, low-voltage and high-voltage motors, low-voltage and high-voltage drives, breakers, and switchgears.

We have other products that may not be as well-known. You can, for example, buy turbine controllers from us.

Furthermore, ABB operates on a cradle to grave philosophy. This means that after-sales service is an essential part of our scope. We can also help in supervision and control.

Is there a plan to diversify ABB’s geothermal portfolio? Are there other regions or geothermal applications being considered?

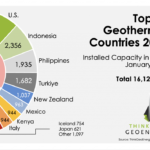

Indonesia is just one of the different places we have sold equipment to. If we look at the last several years, we have supplied a number of generators to geothermal projects in the US and in New Zealand.

A lot of geothermal projects are borne out of some kind of incentive from the government. About 5 to 10 years ago, there a was a huge initiative in Türkiye that led to the construction of several power plants. You had extremely good financing, but you had to produce part of the equipment in Türkiye, which we don’t do for this application.

From my perspective, I can see good possibilities in a lot of areas where geothermal can play a more important role. I am sure that we have products and services that are not yet well-known to geothermal companies.

Do you also envision going into the geothermal heating market?

Geothermal heating is definitely an interesting market because it’s a completely different power level. If I look at Sweden, for example, a lot of the houses are geothermally heated. In a household installation, we can certainly supply a motor or low-voltage components. However, you don’t sell one motor to each household. Instead, you make an agreement with whoever is supplying heat pumps and you supply, let’s say, 200 motors that they will need for the next month.

If you speak about district heating, then it’s something else, that is a bit higher in the power range.

Are there any specific engineering or technical challenges in deploying your technology to geothermal projects?

There are a few things that can vary between different geothermal power plants that are important to remember. The first thing is the type of heat transfer media that they are using.

For single-cycle steam turbines, you are basically feeding the turbine with steam direct from the well with some pre-treatment. For lower temperature resources, power plants will likely be using ORC (Organic Rankine Cycle) technology which uses flammable medias (hazardous area, Ex) or something similar to alcohol, as heat transfer media. With these considerations, you cannot just take any kind of generator, as they have to be classified for that environment.

The presence of hydrogen sulfide (H2S) in geothermal systems is also something that needs to be considered. For example, copper does not like H2S at all. This is something you need to consider, otherwise your machine is going to be ruined in a fairly short time.

From our perspective as suppliers to the oil and gas industry, the EX environment is our bread and butter and it is nothing new to us. H2S is something we need to design for, but we know how to deal with it.

How does geothermal compare to other industries that ABB is working with in terms of complexity, scale, and implementation time?

In terms of project timeline, geothermal can be very unpredictable. Sometimes, you get projects on the fly particularly for repeat clients. Other times, you are quoting for a project that goes live three or four years later. There is no concrete timeline for geothermal projects and it all depends on how the financing.

In terms of complexity, geothermal projects are less complex projects. If you look at it from the ABB perspective, you need something to control the breakers, switch gears, and so forth. Maybe you need a transformer and a generator. You need pumps to pump the brine to the heat exchanger, and you need pumps for the condensers and so forth. So, there is a number of different equipment there, but it is a smaller number compared to a normal oil and gas power plant where you need facilities for waste handling, waste treatment, or smoke handling. The complexity in geothermal is there for sure, notably when working around H2S, but this is not particularly difficult for ABB.

If you look at the scale, the geothermal industry still as a huge potential regardless of how much I wish it would be larger. It is increasing but there is a need for more investment, particularly in the drilling phase of project development. When that funding is ready, the rest of it becomes more controllable.

We are seeing signs of growing interest from geothermal companies. The first discussion I had with a geothermal company was 10 years ago in Cologne, Germany with a company called Atlas Copco. If you compare it to that time, then today is a completely different story.

What have been the challenges that ABB has encountered going into this market?

Energy efficiency is a focus area for ABB, but we also see that some end-users do not have this as a priority yet. In many cases, a new power plant project that is sourcing for motors and generators will go with the cheapest option. There are cases when this choice is dictated by market regulations. But if you go with a generator that can improve the efficiency by just 1%, then that is a lot of extra cash in utilities’ pockets. This is something that we find is totally neglected by the industry when it comes to purchase evaluation.

This non-existent demand on electrical performance is a mistake that I see in the industry, or from whatever regulation is controlling it. We looked at the life cycle costs for an electrical machine, and only 5% of the cost is in CAPEX with the remaining 95% in OPEX. This means that you can have a return on investment with a higher-efficiency motor or generator within a couple of years. And at ABB, we do not build great equipment that lasts for just two years, but we build it to last for at least 25 years.

At this point, I would like to mention something that we are very proud of – we had recently tested a motor with an astonishing efficiency of 99.05%.

What makes geothermal a compelling industry for ABB to go into?

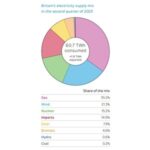

One thing we can all agree on is that tomorrow’s prime source of energy will be electricity. If you look at petrol or other types of chemically stored energy, its efficiency when compared to electricity is much lower. We are not at the point yet where you can recharge an electric car within three to five minutes, but we can all agree that electricity is much better when it comes to efficiency. An internal combustion engine can give you about 30% to 40% efficiency while a large electric motor will at least give you 98%.

Within that context, ABB has been focusing on electricity for many years. We also align very strongly with sustainability, whether it’s recycling equipment or using a more Earth-friendly material. From our perspective, geothermal being a sustainable and environmentally friendly energy source is just a perfect match. I cannot see any industry that is even better for us.

What is ABB’s long-term plan for the geothermal sector?

Geothermal is a young industry, and so there are plenty of suppliers that we have not yet covered. This is especially true in North America where innovations like Enhanced Geothermal Systems (EGS) are creating a growing interest in geothermal. From our perspective, we already have a very wide and very good portfolio of electrical equipment that are needed for the geothermal power plant. Now the task if to make it available to as many as possible.

I am not expecting ABB to be a turbine supplier, as sold that business many years ago. But I believe that we can engage more with all the newcomers in the industry. There are a large number of steam turbine suppliers out there that say that they are into geothermal, but they have not really covered the market yet. I think there will be more and more opportunities for these new suppliers and we are looking forward to working with them in the future.