Fervo Energy reports breakthrough in field-scale EGS project in Nevada

Energy Disrupter

Fervo Energy has announced a major milestone with the successful drilling, stimulation, and testing results from the full-scale EGS pilot project in Nevada.

Fervo Energy has announced positive results of a 30-day well test conducted at Project Red, the company’s full-scale EGS pilot project in northern Nevada.

The results indicate that the well doublet, connected by a hydraulically fractured reservoir, can support 3.5 MW of electricity production (assuming a supercritical ORC cycle) with a flowrate of 63 L/s at high temperature. Gross power output ranged from 2 to 3.5 MW throughout the test. The flow rate and power output achieved during the test exceed the performance of other historic EGS projects.

The drilling and stimulation phase of the project was completed between January 2022 to March 2023. The well testing phase took place from April to May 2023.

“By applying drilling technology from the oil and gas industry, we have proven that we can produce 24/7 carbon-free energy resources in new geographies across the world. The incredible results we share today are the product of many years of dedicated work and commitment from Fervo employees and industry partners, especially Google,” said Tim Latimer, Fervo Energy CEO and Co-Founder.

Fervo’s results from Project Red support the findings of the DOE Enhanced Geothermal Earthshot and show that geothermal energy could supply over 20% of U.S. power needs and compliment wind and solar to reach a fully decarbonized grid.

“Power systems modeling confirms that geothermal can be a critical player in a fully decarbonized grid. Fervo’s successful commercial pilot takes next-generation geothermal technology from the realm of models into the real world and starts us on a path to unlock geothermal’s full potential,” said Jesse Jenkins, Assistant Professor and leader of the Zero-carbon Energy systems Research and Optimization (ZERO) lab at Princeton University.

Related to this announcement, Fervo has published a pre-print of a research article that provides more technical details about the project and its results. The pre-print can be accessed(https://doi.org/10.31223/X52X0B) but has not yet been peer-reviewed.

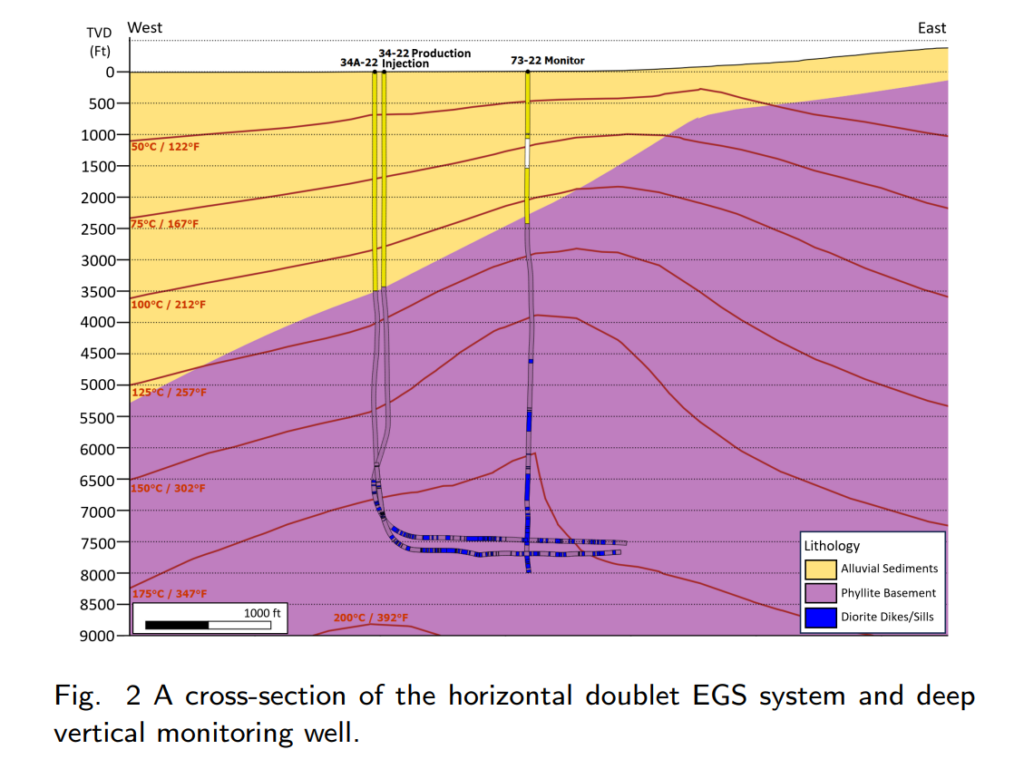

Selection of project site

The project site is located adjacent to the Blue Mountain Geothermal power plant located in northern Nevada. The stratigraphy of the site is characterized by Miocene to present basin-fill deposits overlying Mesozoic phyllites with multiple intrusions of igneous dikes and sills, interpreted to be Mesozoic and Tertiary in age. The Blue Mountain geothermal system is associated with a displacement transfer zone and deep circulation is primarily controlled by N to NE-striking normal faults intersected by a NW-striking dextral-normal fault system.

The drilling is located south of the known upflow and outflow zones of the Blue Mountain geothermal system. Several wells have been drilled in this area, exhibiting conductive temperature conditions and a recognized lack of deep permeability. These conditions made it the ideal testbed for Fervo’s proposed EGS project.

Well design and drilling

Three wells were drilled by Fervo – a vertical monitoring well (Monitoring Well 73-22), Injection Well 34A-22, and Production Well 34-22. The injection and production wells comprise the first-of-its-kind EGS horizontal doublet well system. The lateral sections of the wells were drilled with 9 7/8″ hole size, completed with 7″ casing, extended approximately 3,250 feet (990 meters) horizontally, and reached a maximum measured temperature of 376 °F (190 °C). The laterals of the were landed at a true vertical depth of approximately 7,700 feet (2347 meters).

Horizontal drilling was considered to improve the economics of a geothermal project by providing greater access to the

target reservoir volume, more consistent flow rates, more uniform flow distribution throughout the reservoir volume, and greater total heat transfer surface area. Horizontal well design also offers many engineering design decisions, allowing it to adapt to different geological settings and locations.

Stimulation performance

The two horizontal wells were stimulated using a plug-and-perforate method starting at the toe of the well and moving uphole towards the heel of the well. The stimulation involves pumping of a slurry of fluid and proppant down the wellbore to initiate fractures in the rock.

Injection Well 34A-22 was drilled and stimulated first. A total of 16 stages were stimulated along the lateral, with each stage of roughly the same 150-foot length. In each stage, 16,000 bbl of fluid and 540,000 lbs of proppant were to be pumped at a target injection rate of 100 bpm.

Based on data collected from the in-well fiber optic sensors, fracture breakdown and initiation occurred at 100% of the perforation clusters. There were no evidences of bridge plug failures, indicating that the bridge plugs used in this project were appropriate to the downhole temperature and pressure conditions.

Well testing and performance

The well test involved circulating fluid through the doublet system by pumping fluid down Injection Well 34A-22, through the fractured reservoir system, and up Production Well 34-22. The injection pump located on the well pad provided all the pressure needed to drive fluid through the system – there was no downhole pump or artificial lift system needed.

Pressure at Production Well 34-22 was controlled by a valve located just downstream of the wellhead. Pressure was maintained within 100 to 200 psi, which is equivalent to the anticipated wellhead pressure during commercial operations.

Injection pressures ranged from 1000 to 2000 psi and was maintained below the fracturing pressure of 2300 psi. Injection rates were maintained from 650 gpm to 850 gpm, while production rates typically ranged from 550 gpm to 750 gpm. The 10% to 20% drop was attributed to leakoff of fluid in the subsurface. The production temperature increased throughout the test to a maximum temperature of f 336 °F (169 °C). The stead increase in production temperature confirmed that there was no premature thermal breakthrough.

Induced seismicity

The Blue Mountain geothermal power plant has been under active commercial operations since 2009 and has had no reported cases of induced seismicity. Moreover, the USGS earthquake catalog indicates no recorded seismic events of magnitude M >2 within 20 kilometers of the project area. It was therefore concluded that the Blue Mountain field is an area with minimal natural seismicity.

In July 2020, Fervo commissioned a new local seismic monitoring network consisting of 8 broadband seismometers, a local strong motion sensor installed at the power plant facility, and another strong motion sensor installed in the town of Winnemucca, located approximately 34 kilometers away. The local seismic network was operated continuously from July 2020 through June 2023 in partnership with the USGS.

Based on the understanding of ground motion response in the local area, Fervo established a Traffic Light System (TLS) protocol that consisted of Green (M < 2.0) , Yellow (2.0 <= M < 3.0) , and Red (M >=3.0) thresholds. Seismicity rates increased during periods of stimulation or well testing, but the largest magnitude recorded was an M=1.8 event. This occurred during the 37-day crossflow test. During periods without active operations, relatively low levels of background seismicity were recorded.

Future direction

The results from Project Red represent a major breakthrough in proving that EGS can support steady-state production at a high level of productivity, and that EGS projects can be executed with no major incidents of induced seismicity. The data collected through this pilot will be instrumental in achieving Fervo’s target of more than double the power output for the next pilot design.

This summer, Fervo broke ground on its first greenfield development in southwest Utah, adjacent to the DOE’s Frontier Observatory for Research in Geothermal Energy (FORGE). Revenue and learnings from Fervo’s Utah project will go toward the development of other projects in new geographies.

Source: Fervo Energy