Refineries increase revenue, reduce GHGs with renewable propane

Energy Disrupter

ADVERTISEMENT

A new study by the U.S. Department of Energy’s National Renewable Energy Laboratory shows biorefineries can increase their financial returns by selling renewable propane versus using it as a processing fuel or as a hydrogen feedstock. The financial findings complement the proven carbon reduction benefits of renewable propane for the transportation, commercial, agricultural and residential sectors.

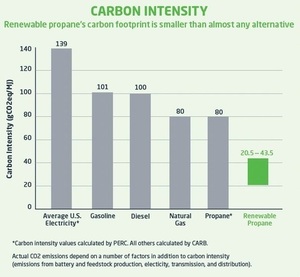

Renewable propane has a much lower carbon intensity than electricity produced in the U.S.

“Our models show that capital expenditure investments have the potential to be returned in as little as two months for large biorefineries or up to 14 months under the worst-case scenario,” said Bob Baldwin, NREL principal scientist and lead author of the study. Baldwin along with NREL researchers Mark Nimlos and Yimin Zhang spent six months studying the economic feasibility of recovering renewable propane from HEFA biorefineries. HEFA stands for hydroprocessed esters and fatty acids and refers to vegetable oils and fats used to produce renewable fuels.

The NREL study considered several alternate use cases for renewable propane at biorefineries, including using it as a process gas, using it to produce renewable/green hydrogen or selling it to a propane marketer or retailer. The study concluded that when sold as a fuel, biorefineries would receive significant revenue by leveraging renewable fuel credits even without a premium on the price of wholesale propane.

“NREL’s study shows the financial upside of renewable propane for refiners, but the carbon footprint story is even more exciting,” said Tucker Perkins, president and CEO of the Propane Education and Research Council that commissioned the study. “When you realize the carbon intensity of renewable propane is significantly lower than grid electricity and other fuels, it is a clean energy breakthrough.”

Biorefineries around the country are being retrofitted to use feedstocks like soybean oil, camelina seed oil, field crop stover, animal tallow and used cooking oil to produce renewable fuels. Renewable Energy Group headquartered in Ames, Iowa and recently acquired by Chevron is one biorefinery of several that is committed to increasing production of renewable propane. In 2021, REG opened a new facility to ramp up production of renewable diesel from 90 million gallons per year to 340 million gallons. This translates to 30-34 million gallons per year of renewable propane, and similar expansions are taking place in other HEFA biorefineries that could easily quadruple this number.

Renewable propane is already available in every state in the U.S. In Sacramento, California, the Elk Grove School District has been using renewable propane for the past few years. “Not only do renewable propane-powered school buses perform well, but they are also helping us achieve our carbon reduction goals,” said Anthony Willis, supervisor of fleet maintenance for the Elk Grove School District in California. “We’re currently running about 20 to 30 of our school buses on renewable propane and will consider transitioning to more of them as older buses are retired.”

The World LP Gas Association estimates renewable propane could meet half of the world’s propane demand by 2050. Today’s U.S. biorefineries have the potential to produce 40 to 50 million gallons of renewable propane annually.