Harnessing geothermal heat through customized OCTG solutions

Energy Disrupter

With a long history in oil country tubular goods and also work in geothermal, Tenaris successfully supported drilling of a well for a geothermal spa in Austria.

With more than six million meters of pipes for geothermal projects since 2016 and throughout the last years, Tenaris has been increasing its focus on geothermal applications, partnering in geothermal activities for power production as well as for direct use and thermal spa, so this release shared with us.

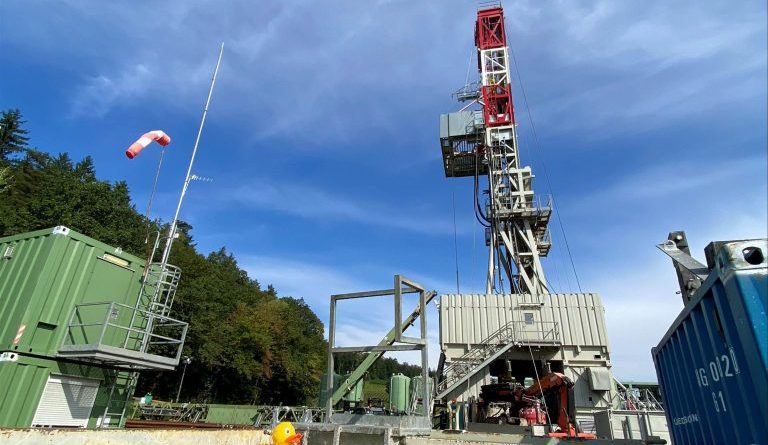

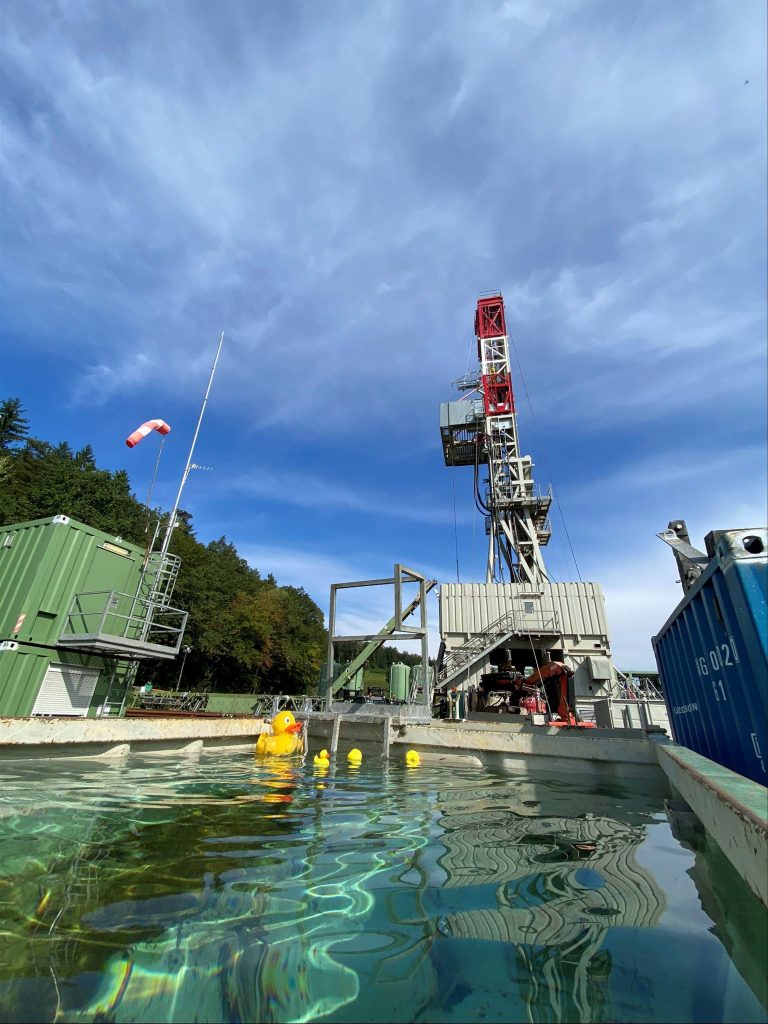

Tenaris’s customized production string for a geothermal well has been successfully run in the Loipersdorf thermal area in Austria. The well was drilled and completed by RED Drilling & Services GmbH, an Austrian drilling company.

“The challenge in the recently drilled geothermal well was to select a technically feasible and cost-effective solution for the expected water type. Tenaris expertise in string design made the difference when selecting the ideal casing. The team addressed various topics in the planning phase providing potential solutions such as the epoxy-phenolic coating TenCoat 8000 (TM). Thanks to the Wedge 563 (R) CB design, handling and installation of the coated casing itself are 100% comparable to conventional casing, and in combination with the running supervision provided, the casing running job could be performed faster than anticipated,” highlighted Thomas Daborer, Well Engineer & Workover Coordinator at RED Drilling & Services GmbH.

The well, with a target depth of around 1,100 meters, produces hot water at 70 degrees Celsius to warm up the thermal water for the spa. In order to guarantee the longest possible operating life of the well, RED Drilling & Services GmbH sought out an optimized solution to protect the integrity of the well for years following its installation.

“From the very first moment we started working on Loipersdorf different options were evaluated with the target of proposing a solution fit to the well conditions and to the operative requirements of our customer,” says Paolo Novelli, Tenaris Energy Transition OCTG Project Director.

For the 9 5/8’’ production string used in Loipersdorf spa, Tenaris experts proposed a solution that consisted in a casing with internal coating along with its TenarisHydril Wedge 563 (R) Corrosion Barrier premium connection. TenCoat (TM) 8000 internal coating is proven to protect against corrosion, high temperature, and abrasion, thus being a cost-effective alternative to Chrome steels or CRA (Corrosion Resistant Alloys). TenarisHydril Wedge 563 (R) Corrosion Barrier differs from other connections due to a corrosion barrier elastomeric ring placed between PIN and BOX which ensure coating continuity in the connection area.

The running of the 98 pipes needed for the casing production string was smoothly completed with the assistance of Tenaris field service in October, without any rejection or remake up.

With more than 30 years of experience in supplying casing for specific geothermal drilling challenges, Tenaris can provide tailored solutions for the desired result, while maximizing the safety and efficiency of customers’ operations. Learn more here.

Source: Tenaris release by email