History made by Heerema with offshore testing campaign

Energy Disrupter

General – testing campaign

Heerema Marine Contractors has tested its novel Rotor Nacelle Assembly (RNA) installation method offshore for the first time.

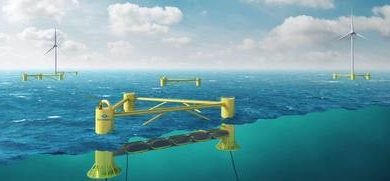

The offshore wind industry is projected to produce 228 GW by 2030, enough to power over 68 million homes. To meet these targets, offshore wind turbines are progressively increasing in size and are being planned for installation in remote locations and deeper water depths.

Due to these market developments, Heerema strategically developed the novel RNA method for the next generation of wind turbines.

The largest technical challenge when using a floating installation vessel is the relative motion between the vessel’s crane and the geostatic foundation of the offshore structure. One specific point of attention within the RNA method is the blade installation, which has been identified as the most critical part of the turbine installation offshore for any vessel.

To combat these challenges, Heerema has developed the guided root end positioning tool, known as the GREPT. This in-house developed blade assembly tool enables offshore handling and installation of blades safely and efficiently.

The development of Heerema’s RNA method has been ongoing over the last two years and has been tested extensively within Heerema’s Leiden Office based Simulation Center. This offshore test put the method into practice for the first time in Eneco’s Prinses Amalia wind park, the Netherlands. The test results will be used to continue improving the RNA method within the Simulation Center.

Vibro Lifting Tool testing

The monopile used was installed in 2018 as part of a previous test project known as SJOR. The SJOR project was the first time a Vibro Lifting Tool had been used with a dynamically positioned (DP) vessel for the installation of a monopile without the use of a gripper frame or similar. This time, the process was reversed to execute the removal of the monopile.

CAPE Holland’s Vibro Lifting Tool (VLT) has been used again successfully by Heerema Marine Contractors to decommission the same offshore mono-pile in combination with HMC Sleipnir’s Dynamic Positioning system.

Apart from loosening and extracting, the mono-pile was re-installed and extracted an extra time and a series of tests were performed to assess soil response and gain further knowledge of the vibro driving technique.

Original Source: https://ocean-energyresources.com/2021/10/19/history-made-by-heerema-with-offshore-testing-campaign/