Call for Europe-wide ban on landfilling wind turbine blades

Energy Disrupter

Industry group WindEurope has called for a Europe-wide landfill ban on decommissioned wind turbine blades by 2025.

It called for the region’s wind industry to reuse, recycle or recover 100% of decommissioned blades, and to not send decommissioned blades from Europe to countries outside of the continent for landfilling.

WindEurope plans to develop a strategy detailing the steps required to accelerate wind turbine blade circularity.

It will work closely with the European chemicals industry, which provides chemical recycling solutions, and other composite-using industries, such as the boating sector, to help create demand for the necessary technologies.

The ban would also apply to other large composite components in the nacelles of modern wind turbines, and the trade body is confident that non-EU European states will also commit to the ban.

“A ban on landfilling wind turbine blades will help accelerate the development of sustainable recycling technologies,” WindEurope CEO Giles Dickson explained.

“Austria, Finland, Germany, and the Netherlands already have a landfill ban in place. But we call upon the European Commission to propose a harmonised European approach.”

Several industry leaders – including Vestas, GE and Aker – have announced plans for blade recycling and recovery in recent months.

These plans are in early stages, but Dickson is confident that such solutions will be ready in time for a 2025 cut-off, and developers will not resort to exporting decommissioned blades out of Europe, he told reporters. Dickson also said he is confident in the UK’s capacity to ban blade landfilling, despite having left the EU.

He also called for legislation to help support the creation of viable recycling value chains and to incentivise a market for recycled materials.

Challenge ahead

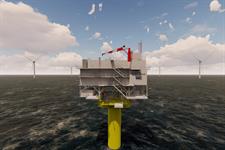

Today, between 85% and 90% of a wind turbine’s total mass can be recycled, with blades accounting for much of the deficit. This is because blades contain complex composite materials – a combination of reinforced fibres, usually glass or carbon fibres, and a polymer matrix.

These composites boost the performance of wind turbines and allow for lighter and longer blades with optimised aerodynamics. However, their configuration also poses challenges for recycling.

Technological solutions to recycle the composite materials in blades exist today, but they are not widely available at an industrial scale and are not cost-competitive.

In Europe’s most mature wind markets, an increasing number of turbines are reaching the end of their operational life.

WindEurope expects around 25,000 tonnes of blades to teach the end of their operatinalife annually by 2025, with the highest number of decommissioned blades in Germany and Spain, followed by Denmark.

Towards the end of the decade Italy, France and Portugal will also start to significantly decommission blades, and the annual decommissioned volume could double to 52,000 tonnes by 2030.

Juan Virgilio Márquez, general manager of Spanish wind energy association AEE, added: “As an industry we are determined to be at the forefront of sustainability and circularity.

“Wind turbine blades are non-toxic and landfill safe but we believe landfilling is a waste of valuable resources. Our commitment to end the landfilling of wind turbine blades by 2025 will help to make sustainable recycling methods commercially viable.”