GE aims to use recycled turbine blades for new wind farms

Energy Disrupter

GE Renewable Energy has signed agreements with Swiss construction firm LafargeHolcim and German waste recycling firm Neowa to explore circular economy solutions for wind turbine blades.

Under a memorandum of understanding, GE and LafargeHolcim explained that they would seek to turn decommissioned wind turbine blades into sustainable construction materials for new wind farms.

In a separate multi-year agreement, GE and Neowa stated they would work together to recycle a number of components – including blades – from decommissioned onshore wind turbines in Germany.

“This is a truly exciting next step in our journey to introduce new circular lifecycle improvements for the wind industry,” said GE Renewable Energy’s chief executive Jérôme Pécresse.

LafargeHolcim’s research builds on the company’s work, under its Geocycle brand, to recover energy from GE’s decommissioned turbine blades after they have been removed from the turbine and shredded.

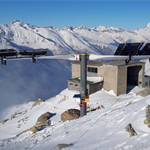

GE and LafargeHolcim are also collaborating on developing wind turbine towers at record heights using concrete 3D printing.

GE has a multi-year agreement with Veolia North America to use decommissioned blades at cement manufacturing facilities across the US.

Meanwhile, GE and Neowa will also jointly explore the potential to expand the former’s blade recycling technology for other countries in Europe.

Nearly 10GW of aging turbines in Europe are expected to be repowered or decommissioned by 2025. Ambitious EU plans on expanding the circular economy approach are driving initiatives of this kind in the wind sector.