Checking in on the Utah FORGE project – Interview with Joe Moore, principal investigator

Energy Disrupter

Learn more about the current state of the Utah FORGE project, its opportunities and challenges and the road ahead from this interview with Joe Moore, Principal Investigator with the project.

The Utah FORGE project, Frontier Observatory for Research in Geothermal Energy is making progress in the research on EGS in the state of Utah in the U.S. To hear more on the current status of the project, we were glad to be able to connect with Joe Moore, Principal Investigator with the project.

Can you please give us an overview of Utah FORGE?

Utah FORGE is a bold move by the U.S. Department of Energy to stimulate the development of electric generation from heat stored everywhere in hot rocks, and not only in those unusual places that are home to conventional geothermal projects.

Conventional geothermal systems have three essential components; a source of heat, water or steam to transfer the heat upward and adequate permeability to allow for fluid migration. Hot rocks in Enhanced Geothermal Systems (EGS) lack the permeability necessary for large-scale heat transfer but offer the potential for utilizing the earth’s energy anywhere in the world. Despite numerous previous attempts worldwide to create the permeability required for large scale commercial EGS reservoirs, none of these projects have produced more than a few MWe and most have yielded low flow rates and low heat recoveries. Permeability within these newly created reservoirs is dominated by natural fractures.

Rather than repeat previous programs, the US Department of Energy through the Geothermal Technologies Office funded the University of Utah to build and manage an international field laboratory to develop and test technologies for creating, sustaining and monitoring Enhanced Geothermal System (EGS) reservoirs. The Utah Frontier Observatory for Research in Geothermal Energy (Utah FORGE) will receive a total funding of $200 M over the period from 2014-2024; half of the funds will support research by external organizations; the remainder will be used for operational costs such as drilling wells and running tests.

The laboratory will function as a dedicated site for technology development and public education on geothermal energy in general and EGS development in particular. Collaboration and involvement of scientists and engineers with a broad range of specialties and affiliations are encouraged to participate in the program. The goals of Utah FORGE are to:

- Gain fundamental understanding of key mechanisms controlling fracture generation, fluid flow, heat transfer, and sustainability of EGS reservoirs.

- Allow the research community to develop, test, and improve technologies needed for EGS development. Many of these technologies will be applicable to both conventual geothermal development and oil and gas.

- Enable rapid dissemination of technical data to the research and engineering communities, natural resource developers, and the general public.

- Enable a pathway for commercialization of EGS across the country.

- Reduce uncertainty and risk for commercial development.

- Demonstrate to the public and regulatory community that EGS can contribute to the renewable energy portfolio of the USA.

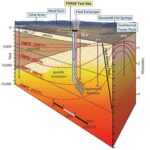

The Utah FORGE site lies in south-central Utah within Utah’s Renewable Energy Corridor. The site is nestled between PacifiCorp’s 36 MWe Blundell geothermal plant, a 306 MWe wind farm and a 240 MWe solar field 16 km north of Milford. Cyrq’s geothermal plant near Thermo Hot Springs and a biogas plant are situated south of Milford. The EGS reservoir will be developed in granitic basement rocks that underly Milford Valley.

The site has already undergone significant characterization and testing as part of the Utah FORGE initiative. New geologic, geophysical and geochemical studies have been integrated with well data characterize subsurface fracture orientations and distributions, stress gradients, permeabilities, temperatures, rock types, and microseismicity. Well 58-32, the initial deep test well, reached a depth of 7536 feet (2297 meters), where the maximum temperature of ~200°C was measured at the bottom of the hole.

When do you expect to start drilling the deep well?

The current plan is to begin drilling the first of two deep deviated wells, 16A(78)-32 in late September, 2020. This well will serve as the injection well for the injection-production well pair that will form the heart of the laboratory. The well will be drilled vertically to 5,940 ft, deviated at 65o to the vertical and then steered to the east-southeast to a measured depth of approximately 10,800 ft and a true vertical depth of 8,480 ft. Temperatures at this depth will approach 225 °C.

What are the biggest advances in understanding thus far?

We have undertaken injection testing in vertical well 58-32 and shown that stimulation of fractures in both uncased and cased intervals is possible. We were able to detect and monitor associated microseismicity using a downhole multilevel seismometer array, a downhole Distributed Acoustic Sensing (DAS) cable, and a high-density array of surface nodal instruments. The results demonstrate critically stressed fractures can be identified and stimulated at relatively low pressures and flow rates. Future stimulations in the deep wells will target and isolate multiple zones of critically stressed fractures, beginning at the toe of the well and then moving upward the heel. New isolation technologies capable of withstanding temperatures exceeding 200 °C are required. Growth of the fracture networks will occur through a combination of dilation and shearing. Lastly, preliminary field results and numerical models show that it is possible to establish a connected fracture network between wells separated by up to several hundred meters.

What are the opportunities that Utah FORGE avails?

Utah FORGE will provide scientific, engineering and educational opportunities to all segments of the public, private, governmental and regulatory communities. The project will demonstrate that EGS is environmentally benign and safe. The project will test and prove multistage stimulation technologies in high-temperature abrasive rocks and create and image fracture-controlled fluid paths connecting the wells. The results will provide basic information on the stimulation and behavior of newly created fracture networks and the mechanisms of heat exchange. All of the data collected on the project will be publicly available. Students and researchers will have access to all of the data, and be able to follow the progress of the project. Finally, Utah FORGE will provide a template for EGS development and a path to commercialization.

The first round of R&D funding of up to $46 million was announced in April with the release of Solicitation 2020-1. Funding will be awarded for the development of new isolation and stimulation technologies, new monitoring techniques, and the collection of basic rock property data. A large number of multidisciplinary proposals were received from private companies, universities and national laboratories. Awards will be announced in the next few months.

What are the technical challenges ahead?

There are numerous of challenges to be dealt with in order to make EGS a viable renewable energy resource. Drilling highly deviated abrasive, hot granite at temperatures of 200oC or more is inherently challenging. Bits and drill string components wear quickly and require frequent replacement. Logging tools, off-the shelf packers and bridge plugs cannot withstand the high temperatures for long periods of time, and equipment failures have been common. Optimizing the drilling program and reducing drilling costs is essential. Once the wells are drilled, sustained fluid flow and heat exchange capable of producing tens of MWe for periods of years must be created.

What can we expect in the coming three to six months?

By the end of the year, we expect to complete the first deep well, 16A(78)-32, and announce the awardees of R&D contracts from Solicitation 2020-1.

To learn more about the Utah FORGE project, check the project website.